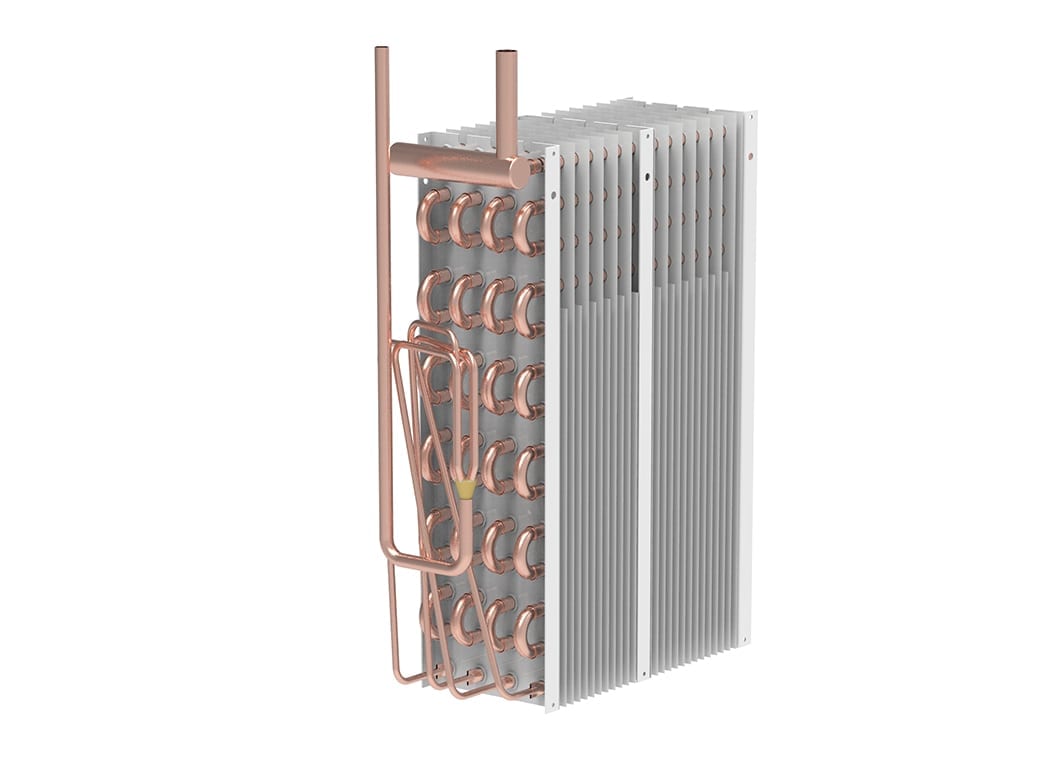

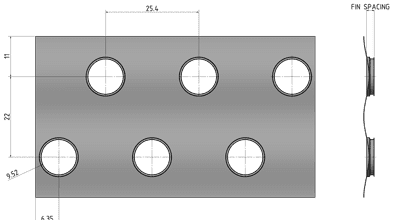

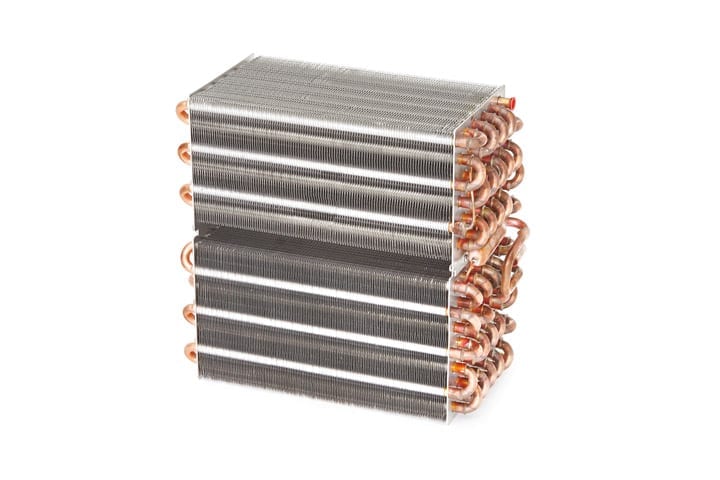

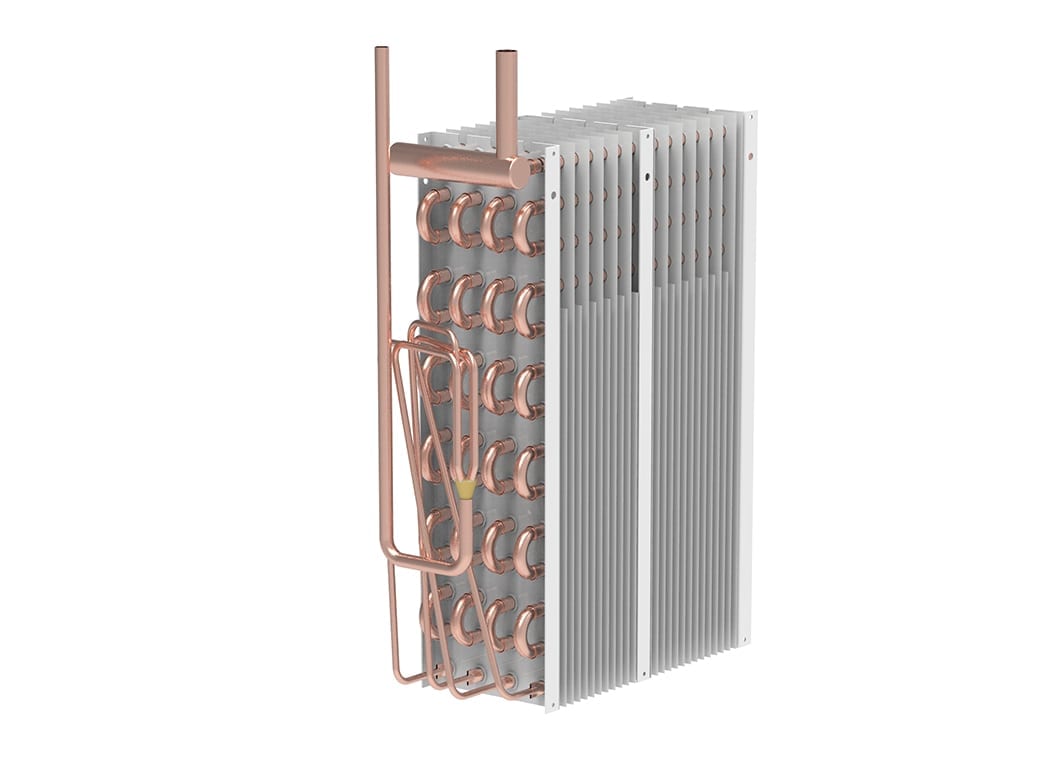

With the progressive reduction in available per head living space and the simultaneous necessity to reduce consumption, domestic driers with heat pump technology have become an absolute necessity. At the heart of energy saving is the pair of evaporating-condensing exchangers. we are the leader in such design and also in the innovaations for the new low consumption classes (A++ and A+++) thanks to the use of technology, materials and available configurations , all designed with mastery by our research and development department.