Research and development are distintive elements in the company philosophy of LU-VE Group. The strength lies in the large-scale investments in R&D which permit the construction of a significant range of innovative products which have represented a point of reference for the major global manufacturers of heat exchangers

LU-VE has the biggest Research and Development laboratories in its sector in Europe and has collaborated closely for many years with the Politecnico di Milano (Polytechnic University of Milan). Numerous other prestigious collaborations have taken place with the Universities of Grenoble, Padova, Chemnitz, Ulster and the Danish Institute of Technology in Århus.

The LU-VE laboratories are equipped with

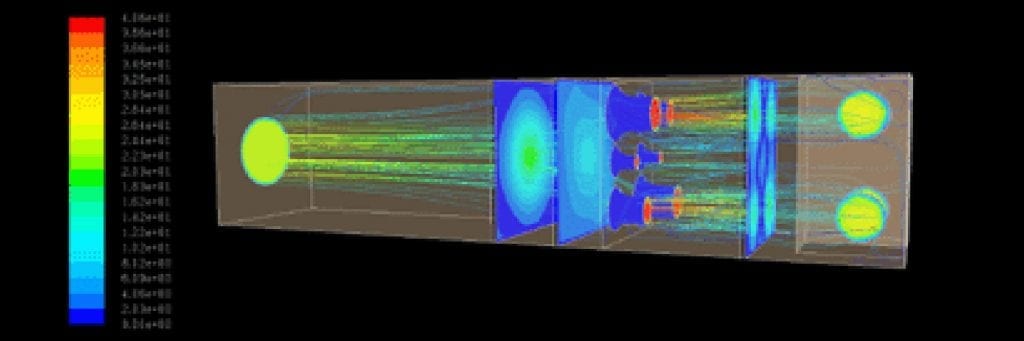

- C.F.D. (Computational Fluid Dynamics) software;

- 5 calorimetric rooms;

- Wind tunnel to study the performance of fins with specialized surfaces;

- Tube performance testing equipment, for the study and optimization of grooved-tube technology;

- 2 aerodynamic tunnels for fan tests;

- CO2 test plant for gas coolers and unit coolers, for the detailed study of CO2 fluid behaviour in the heat exchanger;;

- Sound level test room;

- Test plant for condensers, dry coolers and adiabatic systems;

- Test plant for heat exchanger corrosion and fouling;

- R&D area for the study of controllers and electronics.

The LU-VE laboratories have already been carrying out experiments for several years using CFD (Computational Fluid Dynamics) codes for the study of thermofluid dynamic processes in heat exchangers.

The use of CFD codes applied to finned exchangers increased the understanding of the fluid dynamic phenomena and the processes of heat exchange. As a consequence, it was possible to further enhance the already high exchange performance of the various designs used, continuously renewing the air streams in contact with the special fins and increasing the turbulence caused by them.The smoother airflow obtained thanks to this study of evaporator fins produces less humidity deposition on the fins and therefore less formation of frost, reducing dehumidification. The results of the CDF analyses have consistently been confirmed in experimental tests.

Path lines – CFD output